To mill or not to mill

Ethanol extraction is an attractive option for processors that seek a safe, cost-effective, and high throughput volume to create products that retain high purity levels (90%+). Processors using ethanol extraction know firsthand how versatile and efficient ethanol is as a solvent for extraction, but optimizing their processes requires taking a closer look at the cannabis biomass preparation prior to extraction.

Regardless of the extraction process being employed, post-harvest drying and curing methods are essential steps for downstream product development. Similarly, specific strains of cannabis have unique characteristics that affect extraction efficiency. While this paper does not address these variables directly, we emphasize the important influence they have on the optimization of extraction yields and encourage further investigation and consideration be taken.

What is the main benefit of milling cannabis before ethanol extraction?

There remains active debate regarding the benefits of milling cannabis biomass prior to extraction. From a process efficiency viewpoint, the packing density of the cannabis biomass in the extraction vessel is clearly a bottleneck that benefits from milling. Non-milled cannabis plant material generally experiences packing densities of 100-125 g/L, whereas milled material packs at 225-250 g/L.

However, the milling process increases extraction of undesirable compounds such as chlorophyll. By using large particle sizes for extraction, whole flower for example, the material has most of its cellular structure intact. This, along with utilizing cold ethanol, dramatically reduces the extraction of chlorophyll. This in turn optimizes the extraction of cannabinoids and reduces the post-processing steps.

Quantitative Information

The following quantitative information was captured by Evolved Extraction Solutions during milling tests:

-

Screen Size

Potency- mg/g CBD

Ethanol Separation

Chlorophyll Presentation

Cannabinoid Extraction Efficiency

Pre-Milled

31.2

—

—

—

Coarse Blend (1/4”)

36.7

1.56 gal

0.80 ppm

89%

Medium Standard (1/8”)

37.7

1.96 gal

9.15 ppm

91%

Ultra Fine (1/16”)

41.0

2.27 gal

20.94 ppm

93%

Milling Cannabis Considerations

As shown in the above table, milling can produce desirable (potency, extraction efficiency) and undesirable (ethanol retention/separation, chlorophyll presentation) outcomes.

It is also important to note the positive correlation between uniformity of particle size distribution and the milling blade speed. An optimum blade speed of 300-400 rpm is suggested to maximize the particle size distribution while also protecting the integrity of cannabis volatiles.

Furthermore, optimizing the downstream filtration process following extraction is negatively impacted, from an operational perspective, when cannabis biomass is milled ultra fine (less than 1/16” or 2000 microns). The particulate build-up and subsequent clogging of filtration media with finely milled biomass requires more frequent cleaning and replacement of the filtration systems.

what is an example of optimal milling parameters for ethanol extraction?

Ethanol extraction is optimal for efficient cannabinoid extraction. However, when it comes to milling, the right particle size can result in an extraction that simultaneously reaches optimal efficiency while minimizing undesirable compounds. While our testing revealed that smaller particle size equates to higher total yields, individual compounds (selectivity) often decrease with smaller particle sizes.

The optimal milling parameters that Evolved Extraction has formulated consist of the following:

• 10% moisture content of pre-milled cannabis biomass

• 3000-3500 micron mill size

• 300-400 mill blade speed

• Starting cannabinoid content of pre-milled biomass of >16%

Disclaimer – The content in this article is information of a general nature and does not address the circumstances of any individual or entity. Evolved Extraction Solutions cannot be held liable for any possible claim for damages arising from any decision you make based on information or other content made available to you in this article.

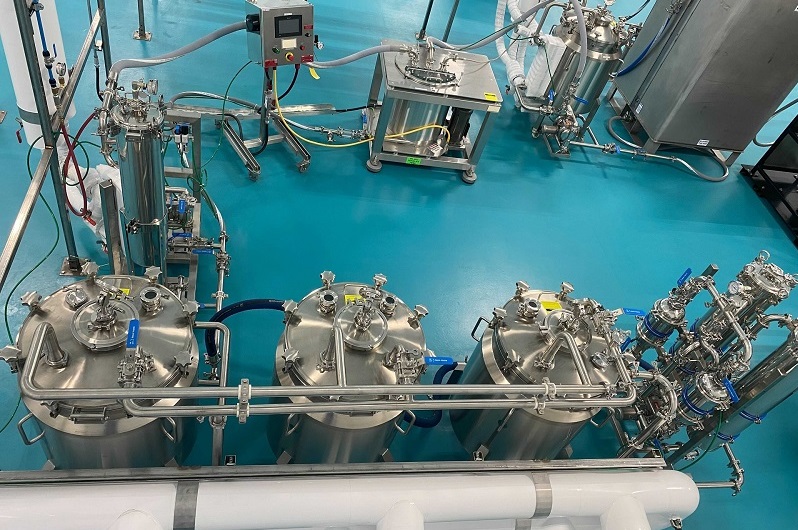

EV-MASS ethanol extraction platform

click to view options

Evolved Featured on Canna Cribs

click for video

Evolved X Adastra: A look inside

click for video