The cannabis extraction landscape has undergone significant shifts with innovations and advanced methodologies continually reshaping the industry. Among these, cryogenic ethanol extraction has emerged as a pivotal technique, positioning itself as the new standard in cannabis processing.

What is Cryogenic Ethanol Extraction?

Cryogenic ethanol extraction, also known as “cryo ethanol extraction” and “cold ethanol extraction,” represents the most recent benchmarks in cannabisextraction efficiency, in the production of THC, CBD and other cannabis concentrates. By using cold ethanol, this method optimizes the solvent’s solubility, effectively enhancing cannabinoid dissolution. Concurrently, it limits the integration of unwanted elements such as waxes, lipids, fats, and pigments like chlorophyll.

Why Cryogenic Ethanol Extraction Matters?

Traditional extraction methods, involving warm ethanol or CO2 extraction, often required several intricate steps, with winterization and filtration of fats and waxes being particularly demanding. However, with the advent of cryogenic ethanol extraction, the production pipeline has seen streamlined operations. Here, the resulting extract is of superior quality, primed for in-line decarboxylation. Post decarboxylation, the extract is ready for introduction into systems such as a wiped film or short path distillation setup. This evolution in the process is especially crucial when focusing on ethanol extraction for CBD and THC.

Ethanol Recovery Systems and Falling Film Evaporators

Commercial-scale cryogenic ethanol extraction necessitates efficient ethanol extraction equipment. Falling film evaporators have long catered to this requirement. A common challenge with many ethanol extraction systems is the frequent manual dispensing of crude oil. This often leaves operators tethered to the ethanol extraction machine, limiting their operational efficiency.

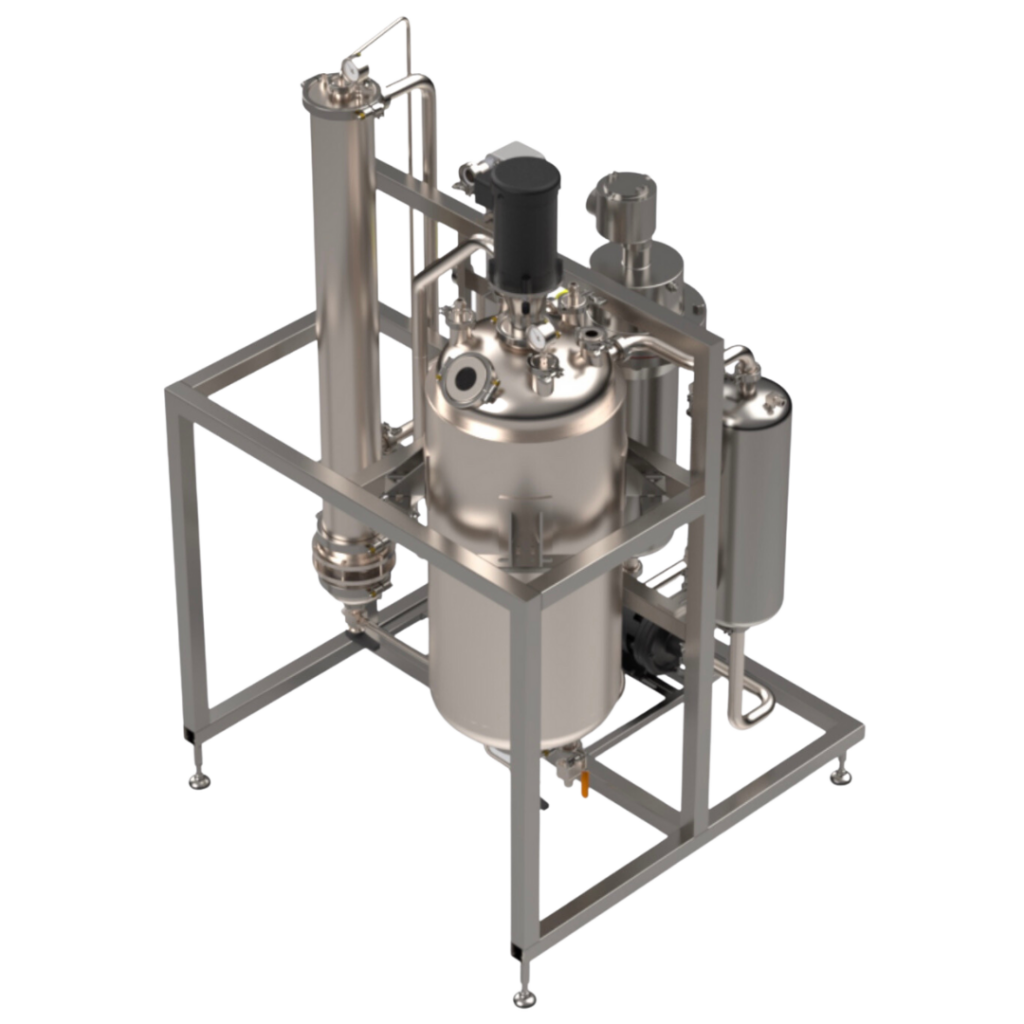

Evolved Extraction’s SRD-30 Falling Film Evaporator addresses this issue by collecting crude into a 150-liter vessel. Once collected, the crude undergoes decarboxylation and is then ready for a streamlined dispensation, optimizing the operator’s productivity.

Decarboxylation Post Ethanol Extraction

The essence of decarboxylation is pivotal for subsequent processing stages. Many falling film evaporators, despite their capabilities, don’t produce oil ready for distillation because they do not have the capability to decarboxylate the oil. This is particularly significant for commercial operations, which rely on wiped film evaporators, which require completely decarboxylated input. A manual intermediate process is thus necessary before distillation.

The SRD-30 Falling Film Evaporator’s design ensures the direct channelling of crude oil into a decarboxylation vessel. Consequently, the oil output is prepped for immediate distillation.

Evolved Extraction Solutions: Setting the New Standard

At Evolved Extraction Solutions, we are committed to advancing the industry’s progress. Our EV-MASS Ethanol Extraction System not only reflects our commitment to excellence but establishes a benchmark in safety, usability, reliability, and efficiency, outclassing the now defunct CUP-30 by Delta Separations which was plagued by reliability and longevity issues. Our comprehensive offerings, spanning extraction to decarboxylation, ensure seamless continuity. With an array of configurations available and a modular design, producers can effortlessly scale their operations. The system is also endowed with an industry leading 2-year warranty, the best in the business.

In conclusion, Evolved Extraction Solutions takes pride in its unwavering dedication to clients and the broader industry. We remain at the forefront of technological innovations, ensuring our partners navigate the evolving cannabis extraction landscape with ease and expertise.