With the right equipment, Live Resin can be pretty straightforward to make, although working with frozen biomass does present some challenges. Whether you’re a live resin rookie or a seasoned pro, this guide and the rest of our Live Resin blog series are packed with essential insights to elevate your craft. Join us to enhance your expertise:

COMING SOON! 👇🏼 Sign up for our mailing list to be notified when it drops!

-How to Make Live resin: 3 Advanced Techniques

-How to Make Live Resin Carts: Scaling Up with THCa Crystals and Liquid Diamonds

What is Live Resin?

What is Live Resin?

Live resin is a top-quality cannabis extract, with high terpene content. Demand for the product is growing quickly because of its outstanding flavor. It’s a favorite among connoisseurs for that reason, especially in the form of Live Resin Vapes.

How is Live Resin Made?

Live Resin is made by extracting cannabis that has been “fresh frozen”, meaning the flowers did not go through the usual drying process before extraction, and instead are frozen immediately after harvest. Then, the frozen buds are extracted using very cold butane and propane in a closed-loop extraction.

Of course the devil is in the details, so stay tuned to the rest of this blog to learn about the whole process and the extraction equipment required.

The Live Resin Extraction Process Step by Step:

The Live Resin Extraction Process Step by Step:

1. Freeze Biomass: Immediately freeze fresh plant material to preserve terpenes and prevent degradation.

2. Extract with Precision: Use a hydrocarbon solvent blend, chilled to -40°C or below, in a closed-loop system to extract the compounds while maintaining low temperatures.

3. Efficient Solvent Recovery: Implement a high-rate, possibly passive, solvent recovery system for efficiency, especially for scalability.

4. Purge Residual Solvents: Utilize a vacuum oven to remove any remaining solvent without damaging the delicate terpene and cannabinoid profile. OR

5. Perform THCa Crystallization: Utilize advanced methods to separate the terpenes from the crystalline THC, thus preserving both and creating ingredients that can be used in product formulations. Check out our Controlled Crash Seminar to learn the tech!

6. Product Crafting:

There are a huge variety of products that can be made from Live Resin, we’ll briefly cover just a few.

a)For Live Resin Carts, separate and decarboxylate THCa, then reintroduce terpenes for flavor.

b)Create Diamonds and Sauce directly due to high terpene content facilitating crystallization.

c)Produce diverse Dab Products (Wax, Budder, Sugar, Caviar) using techniques like whipping or homogenizing, employing a centrifuge for separation if necessary.

For a More Detailed Exploration, See Below!👇🏼

1. Freeze Biomass

The journey to stellar live resin begins with rapid freezing. This is not just any freeze, flash freezing works best as your goal is to freeze the plant matter as quickly as possible. The goal? Preserve those delicate terpenes that give live resin its unique aroma and taste while preventing any ice build up on the biomass.

To lock in the freshness:

- Harvest the finest plant material, including flowers and sugar leaves.

- Vacuum-seal to protect and preserve.

- Deep freeze at -10°F (-23°C) or lower, using flash freezing equipment is optimal.

- Keep the freeze window tight—no longer than 36 hours.

- Transition quickly from the freezer to extraction, maintaining the deep chill to prevent any thaw. If the biomass starts to thaw at all, it could be ruined quickly or you might get unwanted water in your extraction.

live resin sugar, live sugar, what is live sugar, distillate, live rosin, rosin

2. Extract with Precision Temperatures

Precision is paramount in the extraction phase. It’s about the right blend of hydrocarbons, perfectly chilled to capture the terpenes while keeping unwanted elements out. The extraction process demands:

- A solvent blend optimized for terpene retention. We recommend no less than 30% propane, some use higher propane levels.

- A solvent temperature that’s kept frigid at -40°C or below.

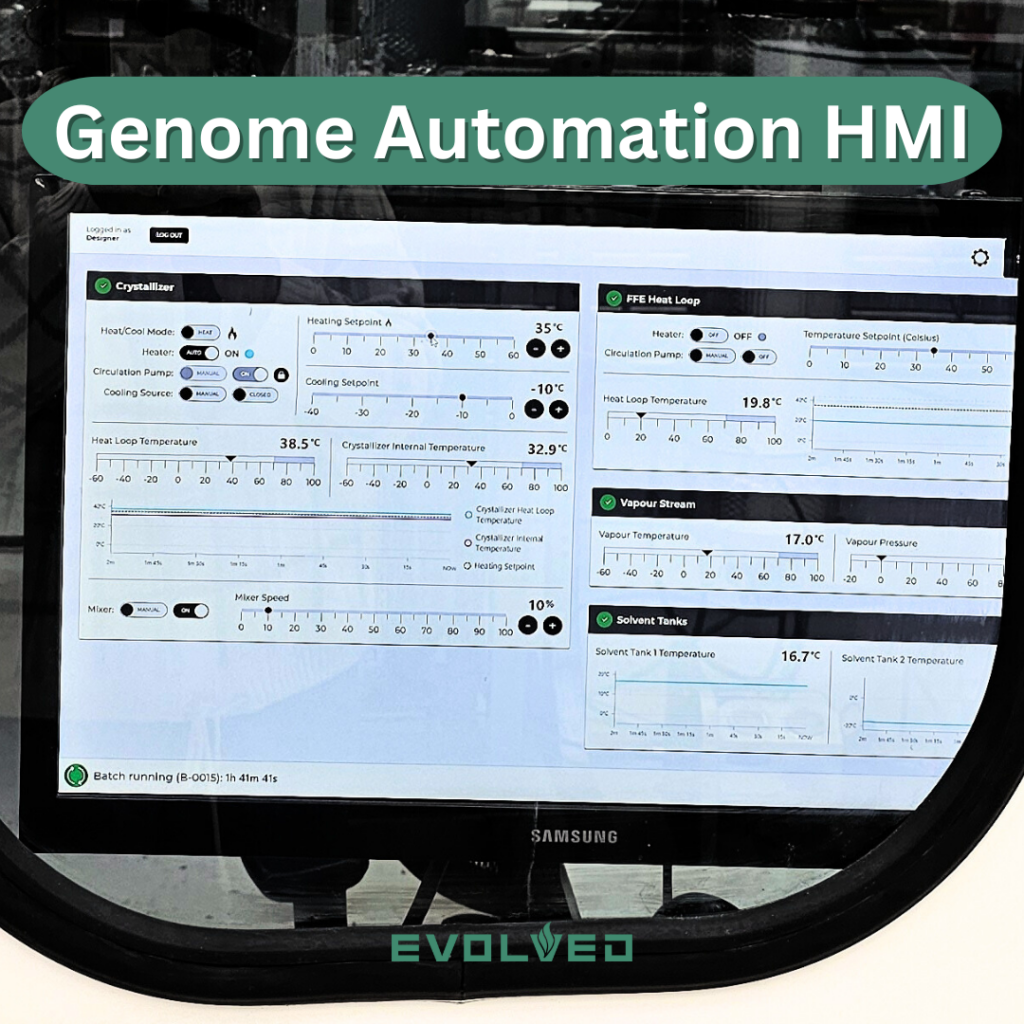

- A high-caliber closed-loop extraction system that marries the frozen biomass with the cold solvent, initiating the magic. Our Genome Hydrocarbon Extraction Platform is tailor made for Live Resin dominance.

- Controlled moderate heat throughout solvent recovery to preserve the terpene profile while separating the concentrate from the solvent. We recommend 30°C (86°F) plus or minus 5°C.

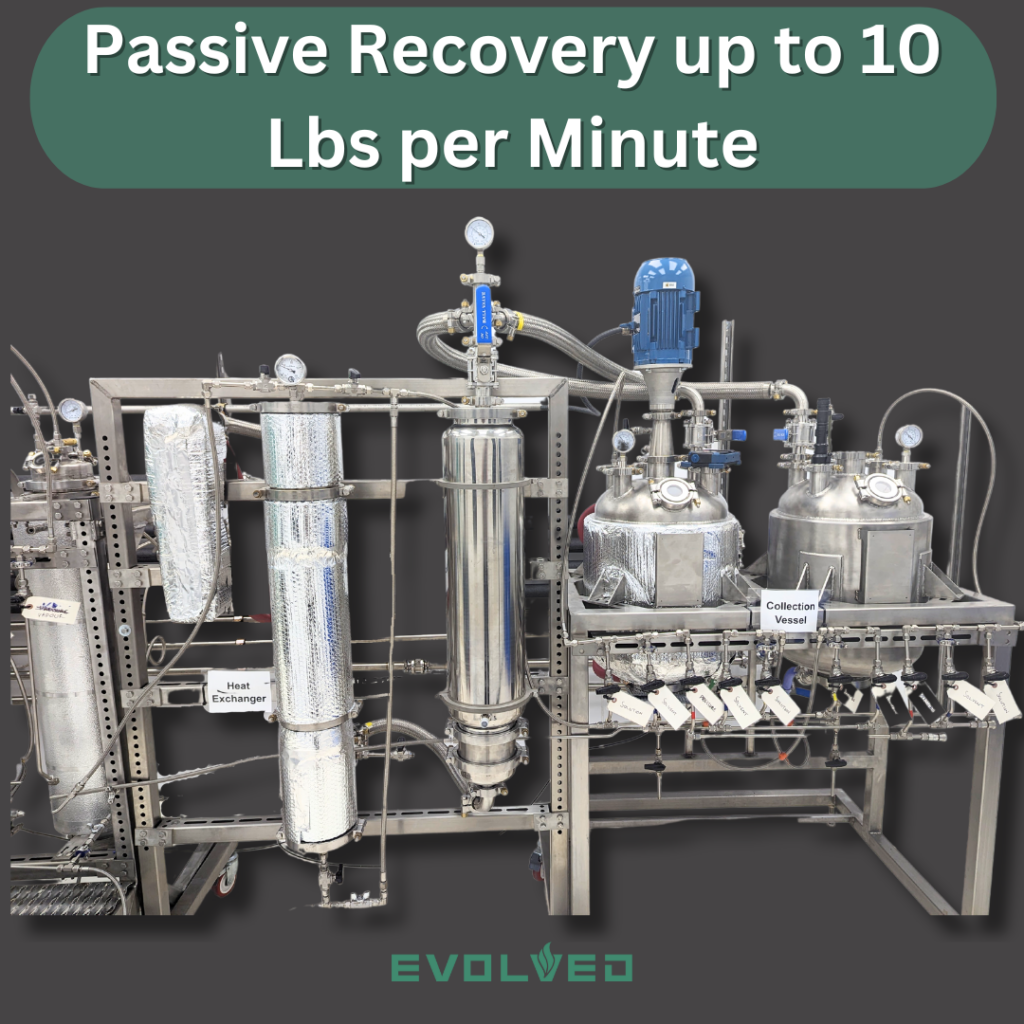

3. Efficient Solvent Recovery

Live resin extraction calls for the recovery of large volumes of solvent quickly. That’s because frozen biomass takes up more volume in your extractor than dried biomass, so the ability to process it quickly is essential to produce any meaningful quantities of live resin. Forget batch based extractors and opt for semi-continuous processing. Top-tier live resin extraction operations:

- Implement closed-loop extractors with exceptional recovery rates.

- Opt for passive recovery systems to push efficiency, hitting rates as high as 10 lbs per minute.

- Embrace modular equipment for easy upgrades, optimizing performance as production scales up.

4. Purge Residual Solvents

Once you pour out the live resin and it sings with terpene-rich notes, the next move is to purge any lingering solvents, which involves:

- A vacuum oven purging process tailored to preserve the full flavor and aroma profile of the live resin.

- A delicate balance of temperature and pressure to ensure solvent removal without damaging those precious terpenes.

5. Perform THCa Crystallization

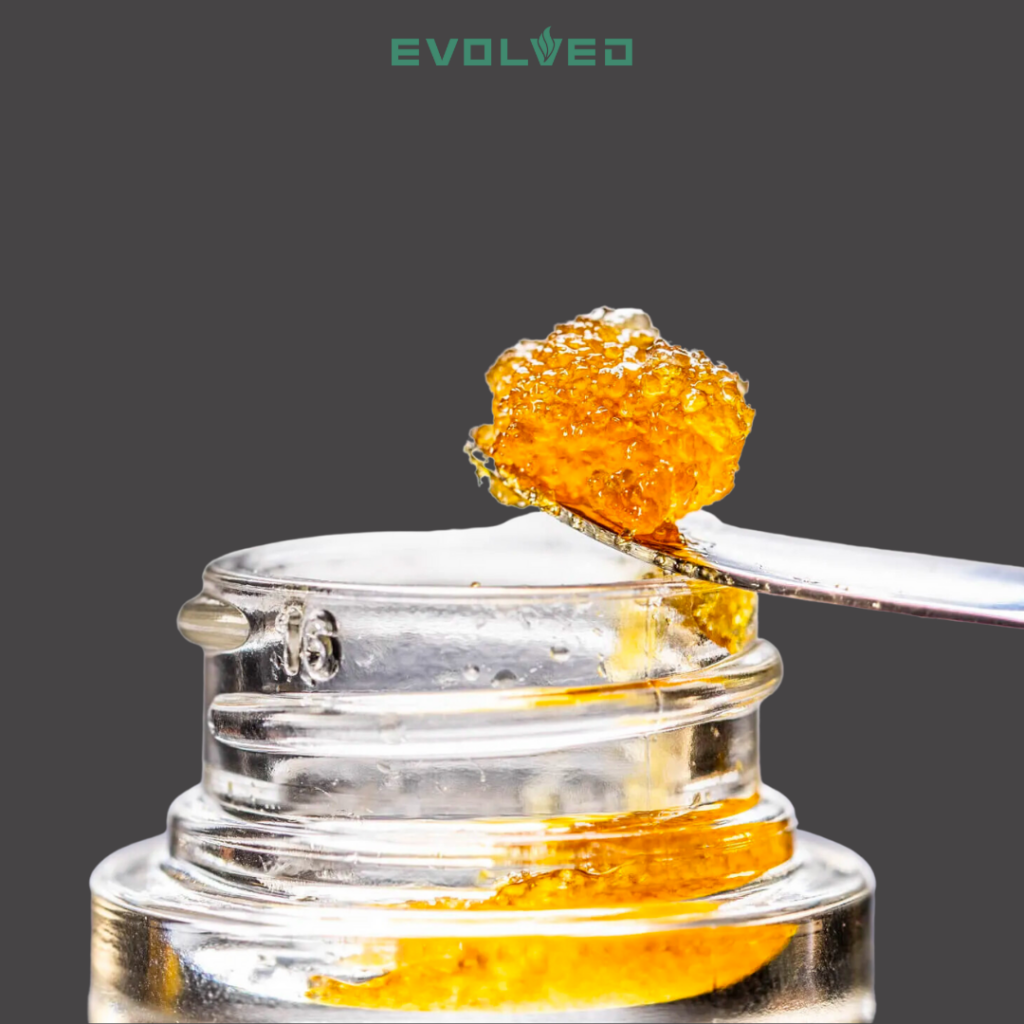

Utilize advanced methods to crystalize the THCa, separating it from the terp sauce. This has numerous benefits for crafting your products. For example, THCa can be heated to decarboxylate into “liquid diamonds” or “crystalate” which is ideal for vape cartridges. Since you separated it from the terp sauce, those flavourful compounds won’t be subjected to heat or degraded at all. The isolate and the terp sauce can also be reformulated back together into a huge variety of product formulations like diamonds and sauce for one. In our Controlled Crash Seminar, you can learn the intricacies of the process.

- Crystalize and separate the THCa isolate from the terpene rich sauce, using the a terpene centrifuge like this one OR:

- The Genome Controlled Crystallization Reactor for scaled-up THCa production, ensuring large and efficient separation batches.

- Controlled decarboxylation to prevent the crystallization that clogs vape carts, if that is your end product.

- Regrow into larger diamonds for making diamonds and sauce. Regrowing diamonds from a crystalline has multiple advantages, including making diamonds about 20x faster than with a diamond miner alone!

6. Product Crafting

The finale of the live resin process is the creation of diverse and high-demand products:

- Diamonds & Sauce: Separate isolate from sauce then grow larger diamonds for fast and easy crystallization. Then reintroduce the terp sauce to leverage the natural properties of live resin.

- High-quality Dabs: Techniques like whipping and centrifugal separation yield the perfect consistency for Budder, Sugar, and more.

- Live Resin Carts: A process that combines carefully decarbed THC with terpenes reintroduced for a premium vaping experience.

- Live resin extraction isn’t just a process; it’s a commitment to quality, flavor, and the essence of the plant. It’s about the finesse of freezing, the art of extraction, and the precision of product crafting. At Evolved Extraction Solutions, we’re not just in the business of selling equipment—we’re in the business of crafting success.

Mailing