Live resin vs Live Rosin

The reputations of Live Resin and Live Rosin have been growing quickly amongst the cannabis-savvy consumer. The increased demand for extracts sporting fresh flavours and well-preserved mono-terpene profiles has caused more extraction professionals and companies to consider adopting these methods. Both methods have their own unique benefits and drawbacks and are also similar in a lot of ways. Industry professionals are well advised to consider the potential costs and scalability these processes may offer compared to standard hydrocarbon extraction or water hash processes.

What is the Difference?

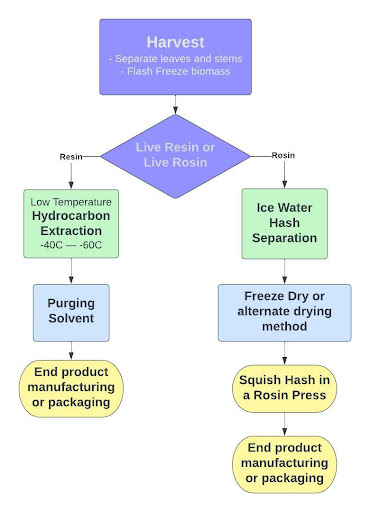

To begin, it is important to discuss some of the major differences. Live Resin is an extraction process, where Live Rosin is a mechanical separation process. The process of making Live Resin consists of using solvents, particularly butane and propane, to soak frozen cannabis to dissolve the terpene and cannabinoid compounds. From this process, a variety of consumer cannabis products can be produced, including diamonds and sauces and various concentrate textures like caviar or batter – really, there is no limit to the kind of textures you can make!

Live Rosin

On the flip side, Live Rosin is either the final product or can be used in such products as infused pre-rolls and occasionally entirely solventless cartridges. The process uses mechanical separation in multiple stages, and that’s why it’s not technically an extraction, as the oil is never dissolved like in an extraction process. That appeals to cannabis purists because the end product does not come in contact with solvents during production. Simply put, the trichomes get sifted to separate them from the plant matter, what we call a mechanical separation.

After the ice water has separated the trichome glands or heads, that hash is separated from the water and then freeze-dried. Then the Live Rosin is squished out of the dried hash in a rosin press. This process is more time-consuming compared to Live Resin, simply due to the bottlenecks in rosin production

Live Resin

Overall, Live Resin provides a higher yield. The use of a solvent allows a higher proportion of cannabinoids and terpenes that exist in the biomass to be collected. It’s also more easily scaled and provides a product that is in the price range of a large base of consumers. Live Rosin demands a premium, and for good reason but the market size remains a bit smaller due to the higher cost of production and resulting product price to consumers. It is important to note that both of these processes are more time-consuming than other, more traditional extraction methods relative to the amount of oil that is produced. Both Live Resin and Live Rosin use frozen cannabis to produce their end products.

The biomass is harvested and then immediately frozen to prepare for the extraction process. This creates a risk with both Live Resin and Live Rosin producers. They must ensure the biomass is frozen properly or risk some crop loss between the time when it is harvested and extracted.

Crop loss usually occurs because of improper freezing or transportation methods. In addition, by using biomass that hasn’t been dried, it has 400% or more volume and five times the weight compared to dried biomass. This causes many considering Live Rosin to hesitate, as the difficulty in scaling and increased labour costs may not be feasible. Of the two, Live resin does provide greater opportunity to lower production cost by scaling up production. the larger the scale the lower the production cost on a per gram basis. Evolved has the right tools for the job when it comes to scaling up live resin production to great heights in regulated environments, so make sure to check out our Genome Hydrocarbon Extraction Platform for more information on that.

Conclusion

To conclude, both live resin and live rosin produce a smaller-than-average yield, though it’s not all doom and gloom. Small yields can be offset by high value and saleability. These processes produce a sought-after, connoisseur-quality product with extremely high terpene content and gassy profiles. In addition, if these processes can be done at the farm where the flower is grown, there is an opportunity for a reduction in cost of production relative to competitors – plus scaling up Live Resin production is possible, which can compensate for the lower yields. Companies in the cannabis industry have developed a competitive advantage by addressing consumer demand for top-shelf products. Your team might want to consider capitalizing on a potentially lucrative niche within the market by creating Live Resin or Live Rosin products to stand out from the pack, and delight your customers.

live resin vs rosin